The University of Texas Medical Branch

Hurricane Ike Infrastructure Recovery and Resiliency Projects

Hurricane-resilient and $3 million annual savings.

In 2008, Hurricane Ike flooded over one million square feet of UTMB campus buildings to depths of six feet. Affiliated Engineers supported recovery efforts with assessments helping to secure FEMA funding. However, Ike created a long-term opportunity to optimize both capital investment and operational spending with engineered resiliency and efficiency. Put to the test by 2017’s Hurricane Harvey, all systems functioned normally, buildings remained in operation, and patients were accepted throughout the event. There was no significant impact to the institution.

UTMB healthcare campus hurricane resiliency: watch this 3 min. video to find out how AEI did.

Rather than replacing in kind, AEI and UTMB established an approach to: protect utility sources and distribution; provide 15MW of on-site microgrid combined heat and power to supplement outside electrical utilities and allow islanding; and, introduce district hot water heating in place of steam (retained for research labs). The two new CHP plants can save approximately $3 million annually, compared to conventional systems, with a 5-year simple payback.

- 50%

- more efficient

5+ miles of highly corrosion-resistant hot water piping reduces susceptibility to storm damage and can save over 10% of heating load through lower line loses.

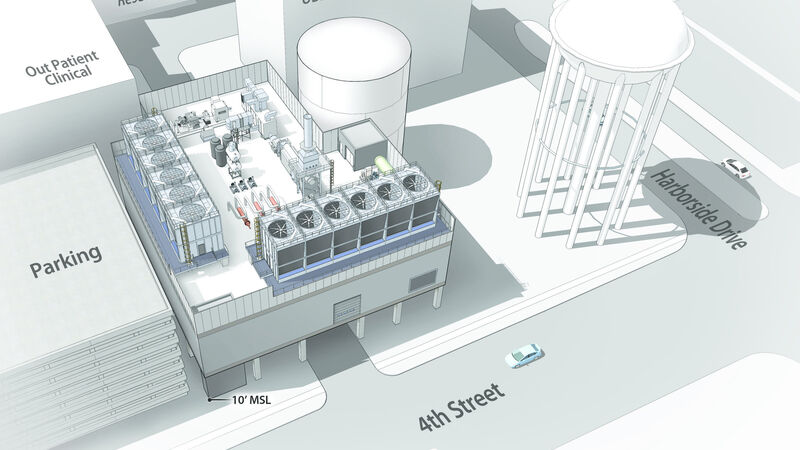

Boilers and chillers were either elevated or protected behind floodwalls.

Protected by a 14-foot (20-foot MSL) floodwall, the new 7.5 MW West Plant includes a 5.5 MW gas combustion turbine, two 1 MW diesel generators, a 75,000 pph heat recovery steam generator, and a 2M gallon thermal storage tank. Elevated 18 feet above ground level (30-foot MSL), the new 7.5 MW East Plant includes two 3,550-ton electric centrifugal chillers, a 5.5 MW gas combustion turbine, a 2 MW condensing extraction steam turbine, a 75,000 pph heat recovery steam boiler, one 1 MW diesel engine-driven, black-start generator, and 2M gallons of chilled water thermal storage. 5+ miles of distribution piping conforms with European Standard EN253.

“UTMB lost $180 million in revenues while coming back on line from Ike, but they still took the farsighted response of improving operational efficiency as part of preparing for future extreme weather.”

- 15MW

- CHP