Collins Aerospace

Airplane Power Systems Integration Facility (APSIF)

Transforming aircraft power systems with the Boeing 787 Dreamliner.

The successful launch of Boeing's 787 Dreamliner marked the dawn of carbon fiber construction and electrical flight systems for commercial aviation, improving fuel efficiency, performance, environmental friendliness, and passenger comfort. UTC Aerospace Systems (formerly Hamilton Sundstrand) built the Airplane Power Systems Integration Facility (APSIF) to provide Boeing with fit and functionality proof-of-concept of the aircraft’s advanced environmental and flight control systems. AEI provided cost estimating, mechanical, electrical, fire protection, and instrumentation and controls design services for the facility.

- 20%

- more fuel efficient.

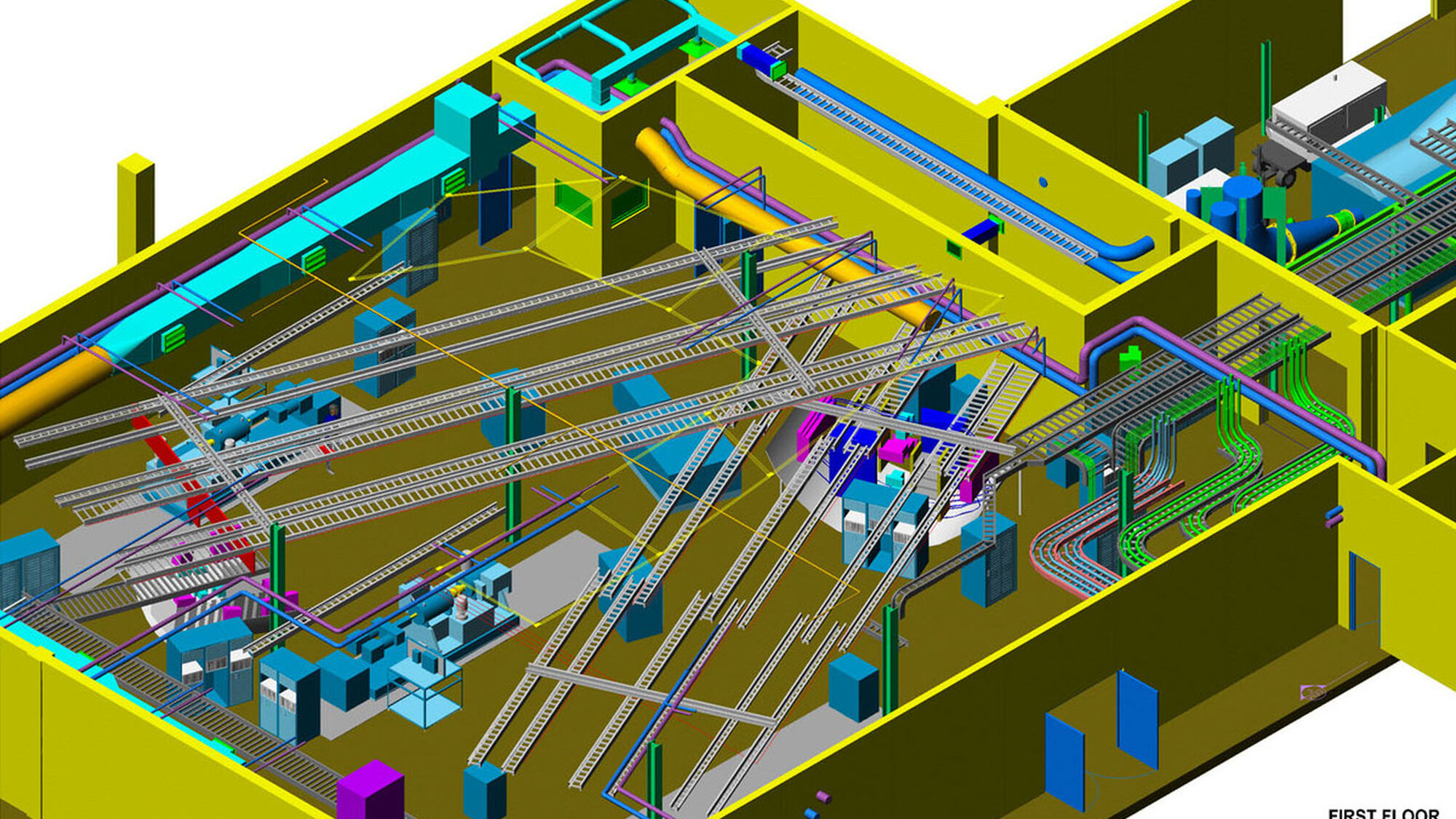

The Dreamliner replaces the pneumatic and hydraulic power sources of traditional airliners with electrically powered compressors and pumps, reducing the engine load by 35%, in turn improving fuel efficiency and increasing thrust. The 1.45 megawatts of on-board power is five times that of conventional pneumatic systems. The 33,000 square foot APSIF replicates the Dreamliner’s AC and DC electrical power, voltage, and 400Hz frequency characteristics to allow testing in a laboratory environment, which in the past could only be performed on a test airplane in flight.

AEI implemented UTC’s current return network design – compensating for the non-conductive nature of carbon fiber – with multiple bus bars above the cabin ceiling and below the floor. Specific attention was given to separating “clean” and “dirty” power, and non-ferrous cable trays and fiberglass drill rods were deployed to avoid EMI. AEI also designed the configuration management system to marshal over 1,000 harnesses (30 conductors per harness), and assisted in tagging, ring-out, and debugging.

The Dreamliner’s electrically powered systems include engine start, cabin pressurization, wheel brakes, and horizontal stabilizer trim. Electro-thermal mats on the wing slats provide ice protection rather than conventional hot bleed air.

- 5x

- the power of pneumatic systems.