Stanford University

Stanford Energy Systems Innovations

Revolutionizing campus energy use.

Stanford University's Energy Systems Innovations (SESI) project transforms power generation campus-wide, shifting from the use of fossil fuels to electricity-based energy supply and heat recovery.

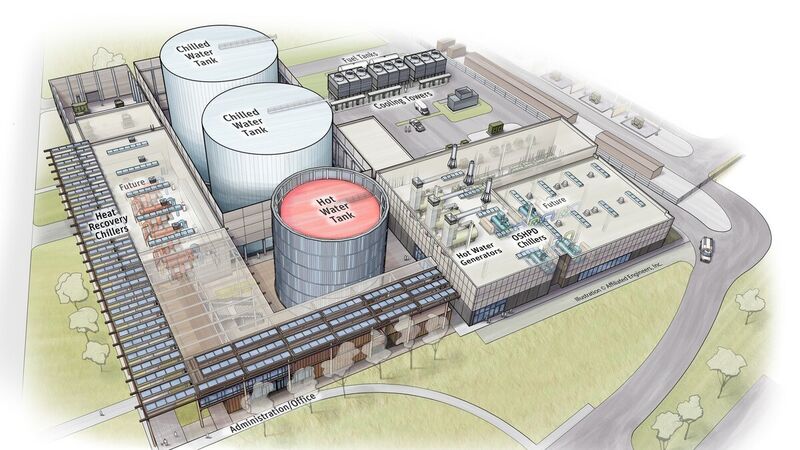

As SESI's prime consultant and lead engineer, Affiliated Engineers analyzed energy production options, evaluated capital and operating costs, and assessed financial and energy risk through 2050. We then designed and directed the implementation of SESI’s five major components — heat recovery/TES plant, OSHPD plant, new piping distribution, building conversions, and 100MVA substation — through multiple jurisdictional authorities to operation within five years.

Designed for a peak load of 28,000 tons of cooling and 350 mmbtu/hr heating, the new systems replace a fossil fuel CHP plant with electric drive heat recovery chillers that — along with standard chillers and gas-fired hot water generators — capitalize on daily heating and cooling overlap to meet 88% of the campus and hospital heating demand with recovered waste heat.

2Mgals of hot water and 10Mgals chilled water thermal energy storage provide load shifting to off-peak electric rates and accommodate high demand periods. SESI is 70 percent more efficient than the previous system.

These heat recovery chillers, along with conventional chillers and gas-fired hot water generators, capitalize on the daily heating and cooling overlap to heat the campus and university hospital with recovered energy. The campus-wide energy system overhaul, converting steam to hot water, utilizing heat recovery and thermal storage, reduces the carbon footprint by 68% and potable water use by 18%.

- 88%

- campus heating load met by heat recovery

Two million gallons of hot water and 10 million gallons of chilled water Thermal Energy Storage accommodate high demand periods and balancing of heating and cooling loads with the heat recovery chillers.

Central Energy Facility

A new 100 MVA, 60kV:12.47kV substation allows flexible management of Stanford's energy supply platform, which is 65% derived from renewable sources.

The Central Energy Facility (CEF) administrative buildings incorporate natural ventilation, heating and cooling radiant floor and ceiling sail systems, and phase change materials. Combined with the 175kW of installed PV on the CEF trellis, these buildings achieve net-zero energy (NZE) operation.

From its NZE administration building to the visual expression of its engineering elements, the CEF is a testimony to the vision and values of a world-leading university committed to sustainable planning and living.

Overview of new central utility plant.

- 12Mgals

- thermal energy storage

Long-Term Impact

Conversion of 155 campus buildings from steam to hot water was accomplished using new heat exchanger stations at each building and over 22 miles of a direct buried, highly insulated, low loss hot water piping system conforming to European Standard EN253.

SESI became operational in 2015 and has exceeded its projected energy savings with greenhouse gas emissions reduced by 68% since 2011.

“The Stanford Energy System Innovations project represents nothing less than a revolution in the way campuses in the U.S. should be heated and cooled.”