Promega Corporation

Kornberg Center

Supporting next-generation science and sustainability.

Promega Corporation (Promega) is a leader in providing innovative life science solutions and technical support to scientists and technicians in the pharmaceutical and biotechnology industries; clinical, molecular diagnostics, forensics, paternity, academic, and government research laboratories; and agricultural and environmental testing.

To support its mission and continued organizational growth, Promega embarked on a comprehensive expansion of its primary headquarters location, significantly increasing operational capacity through a state-of-the-art research and development (R&D) facility comprising 280,000 square feet of new construction, as well as an expansion of the campus’ primary central utility plant.

Maintaining an emphasis on occupant comfort, building performance, and energy conservation, AEI provided mechanical, electrical, and piping/plumbing engineering; fire protection; technology; instrumentation and controls systems design; architectural lighting; construction administration; and sustainability engineering/energy modeling services.

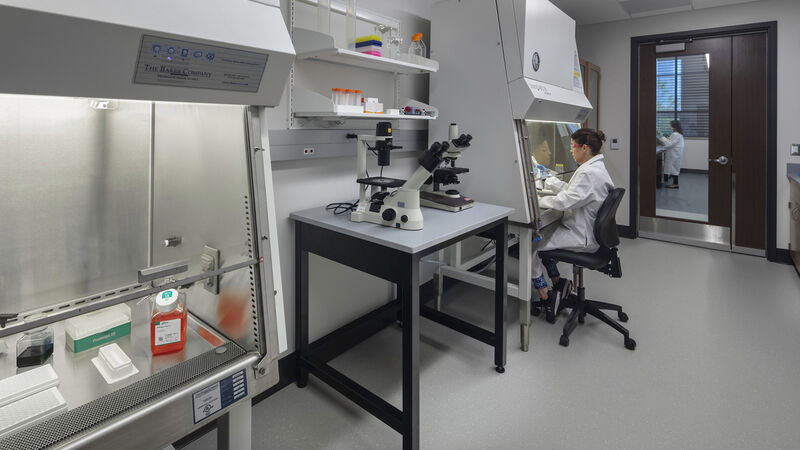

Technically advanced, flexible laboratory environments support Promega’s robust research and development portfolio.

Advanced Laboratory Research Environments

With staff previously dispersed across the existing campus, the new facility effectively consolidates seven R&D teams while incorporating approximately 30 percent designated shell/open space to accommodate future growth.

Space types include dedicated cell culture hoods, integrated instrument rooms, specific core facilities, internal meeting spaces for in-lab meetings, and an open area for a future build-out. The structure also provides space for the use of virtual reality technology, which can help accelerate molecular-related research and discovery.

- 65%

- reduced energy use

Specialized labs support complex research and development initiatives in molecular biology and biochemistry.

With an emphasis on collaboration and transparency, the Kornberg Center features direct lines of sight among space types, from research functions to the primary atrium.

Referencing a core goal to elevate overall user experience, the building maximizes transparency through the use of open work environments across key areas — including laboratories and associated support spaces, workstations and office areas, collaboration hubs and conference rooms, fitness/wellness facilities, café/kitchen areas, and the primary atrium.

Direct lines of sight among multidisciplinary research functions and teams further enhance visual continuity among varying facility space types — fostering passion, connection, and a sense of purpose among staff.

Situated adjacent to the central utility plant supporting the overall campus, the Kornberg building (right) incorporates a vegetated green roof with 672 photovoltaic arrays for on-site renewable power generation.

High-Efficiency Central Utility Plant Operations

Stemming from a previous utility master plan — also completed by AEI — this project includes an expansion of the existing central utility plant (CUP).

Centralizing primary utility operations from a single location, the expansion doubles existing CUP thermal capacity and associated distribution systems, ensuring optimal heating and cooling of all existing, new, and future campus buildings.

- 672

- photovoltaic panels

- 313,000

- kilowatts per hour generated annually

Two floating, wood-inspired walkway bridges within the four-story atrium contribute to a heightened sense of community while maximizing natural daylighting, ventilation, and exterior views.

Sustainable Design Measures

Maintaining a dual focus on user experience and environmental stewardship — contributing to a 65 percent reduction in overall energy use in comparison to similar campus facilities — AEI collaborated with the project team to implement a wide range of high-performance design measures, including:

- Double skin facade

- Radiant heating and cooling

- Geothermal heating and cooling

- Water use

Double Skin Facade

Through an innovative double skin facade — double-walled construction featuring an exterior wall comprised of storefront glass and an interior wall separated by a three-foot air space — the design significantly improves thermal comfort while enhancing energy efficiency through reduced solar heat gain to internal spaces.

Floor-to-ceiling glass walls with an automated shading control system allow natural daylight to penetrate deep into the building, optimizing both occupant experience and energy efficiency. The control system utilizes roof-mounted sensors to track sun movement, adjusting window shades accordingly and thus reducing solar heat gain and glare.

Radiant Heating & Cooling

To reduce the overall energy required for facility-wide thermal distribution, radiant heating and cooling technologies were deployed. This strategy effectively separates thermal loads from building ventilation requirements through embedded piping in the concrete structure (radiant mass floors/ceilings), suspended ceiling radiant panels, and active chilled beams.

In addition, the entire facility is ventilated utilizing 100 percent outside air — improving overall indoor air quality. The integration of total energy recovery wheels is used to recover both sensible and latent energy from exhaust air, which is then used to pre-condition the incoming outside air.

An exposed ceiling featuring suspended acoustic baffles ensures optimal heating and cooling from the radiant system located in the slab above while providing sound isolation for workstation areas.

- 22 miles

- in-floor tubing for radiant heating & cooling

Geothermal Heating & Cooling

Supporting the campus’ central utility plant and overall thermal capacity for the new R&D facility, AEI also implemented a geothermal heating and cooling system — designed to extract energy from the Earth through 56 closed-loop, vertical boreholes, each extending 450 feet deep.

Widely recognized as a clean, renewable source of energy, this high-efficiency system allows for simultaneous heating and cooling — providing heat during cooler months and transferring heat to the ground in warmer months — while significantly reducing total energy costs.

Water Use

Water-efficient technologies incorporated include a dedicated rainwater collection system, which captures, distributes, stores, and repurposes rainwater for alternative use.

Comprising two, 25,000-gallon underground storage tanks, approximately one million gallons of rainwater can be harvested annually. Once collected, filtered, and treated, the water is redirected to either the Kornberg Center for toilet flushing purposes or the CUP and used as make-up water for the cooling towers.

- 1,000,000

- gallons reclaimed water

ASTM Type III high purity water with a resistivity of four megohms is produced and continuously circulated to support research throughout.

Working toward a targeted energy use intensity (EUI) of 115 kBtu/sf/yr, additional sustainable design strategies include:

- Naturally ventilated open workspaces, atria, and non-laboratory areas utilizing the double skin facade

- Reduced ventilation rates for open laboratory spaces operating at 4/2 air changes per hour (ACH)

- Green roof with photovoltaic array generating approximately 313,000 kWh annually

- Displacement ventilation with thermally activated slabs in open workspace areas

- Expanded thermal comfort range in non-laboratory areas

- Active chilled beams in laboratory areas

- Radiant mass floor

AEI’s design ensures that all mechanical equipment, such as in-line circulating pumps used for pumped heating and chilled water coils in air handling units, is easily accessible for maintenance purposes.

Biophilic Design & Lighting

A distinguishing feature of the Kornberg Center, an emphasis on biophilic design connects occupants with the natural world outside while contributing to building sustainability goals. Mass timber is used throughout, providing a durable, cost-effective, low-carbon alternative to traditional construction materials.

Augmenting a commitment to human-centric design, the new R&D facility also emphasizes the use of lighting. Natural daylighting permeates the perimeter spaces through the building’s energy-efficient, double skin facade — simultaneously pouring into the grand central atrium through a 360-degree clerestory and skylight.

Warm, 2700K lighting implemented throughout the varying public spaces and office areas further complements the rich mass timber structure and wood-inspired materials. In critical research and laboratory spaces, 3500K lighting enhances visual acuity, contributing to an elevated user experience and increased productivity.

Featuring the latest telecommunications equipment and user-inspired lighting design, this meeting space offers views into the Kornberg Center’s multi-level atrium.

Linear service corridors provide an infrastructure spine to support flexible, specialized laboratory environments while also creating “back of house” space for equipment and material movement.

“Kornberg Center is a catalyst to innovation. Along with the advanced technology, the building design itself inspires inventive thinking. ”